PSPE-K Case

Development of a CRM system for a distribution company

In modern business, effective management of information and processes has become a key success factor for any company. This is especially important for distribution companies that work with large volumes of data, multiple products and entire networks of distributors and customers.

In this case, we tell how we took part in the development and quality assurance of a CRM system for the PSPE-K company.

About the project

PSPE-K could not find ready-made CRM solutions on the market that could take into account all these specific needs. Standard systems did not support the required level of customization for service planning and spare parts management. Therefore, our task was to create a specialized CRM system that would unite the management of orders, products, warehouses, prices and dealers, and would also help to effectively plan maintenance and spare parts replacement.

Goal

Our goal was to develop a CRM system that would allow PSPE-K to:

Manage orders from dealers and customers.

Optimize product, spare parts and price management processes.

Automate inventory management and spare parts replacement.

To facilitate interaction with dealers and control over service maintenance.

Stage №1

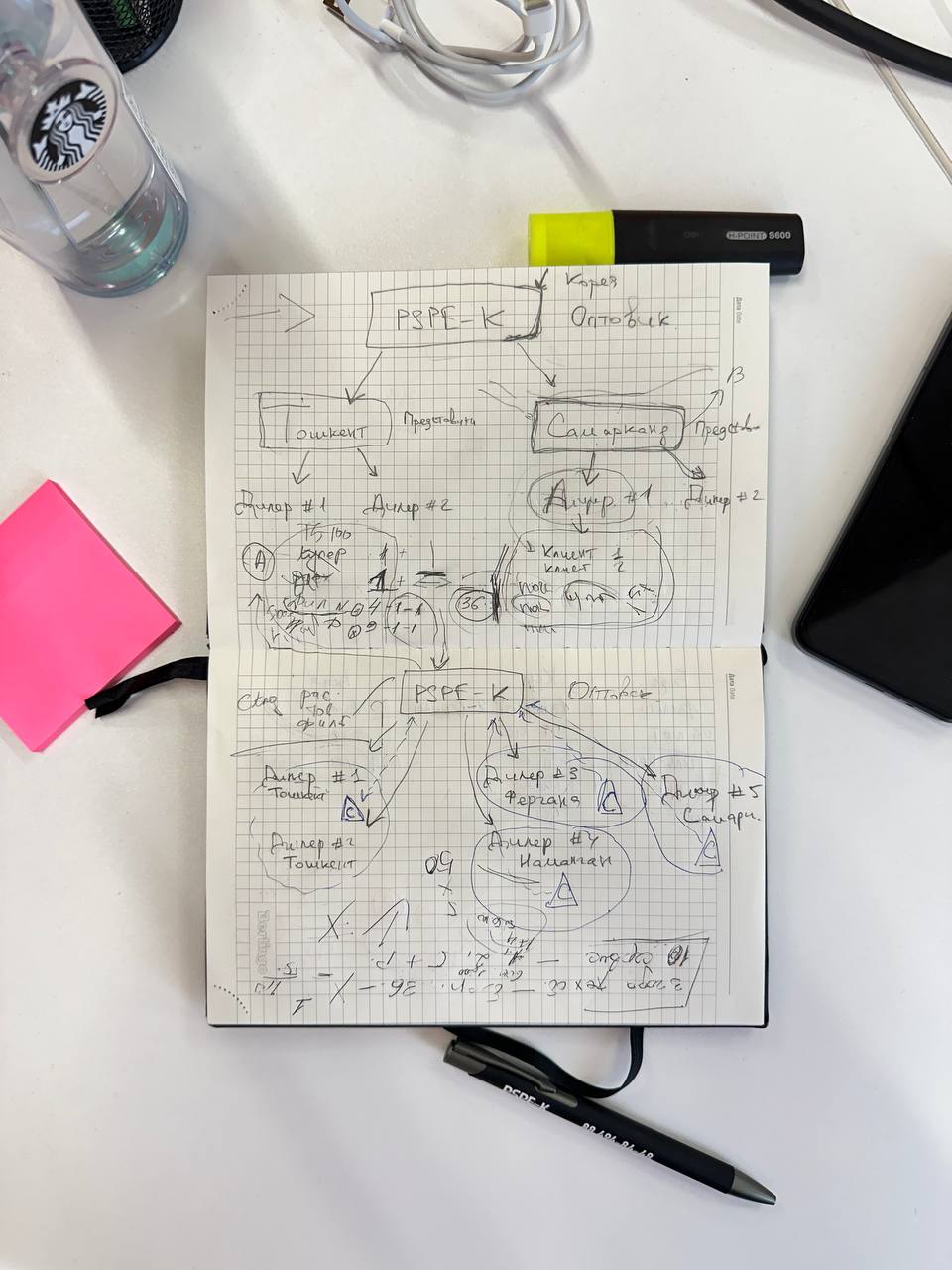

Analysis and planning

We conducted a deep analysis of PSPE-K's business processes to understand how the company manages not only sales but also service of goods. It was important to take into account the need to replace spare parts and plan these works.

Stage №2

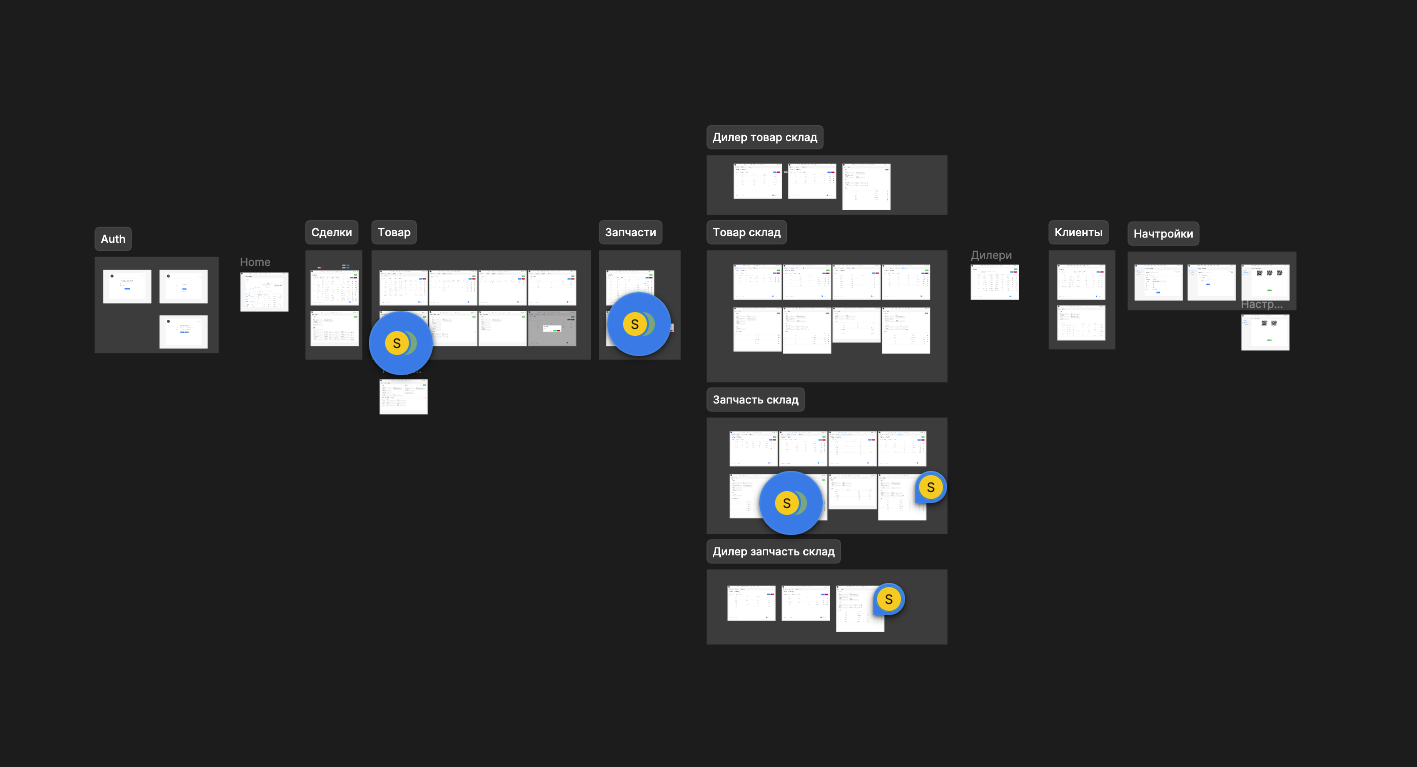

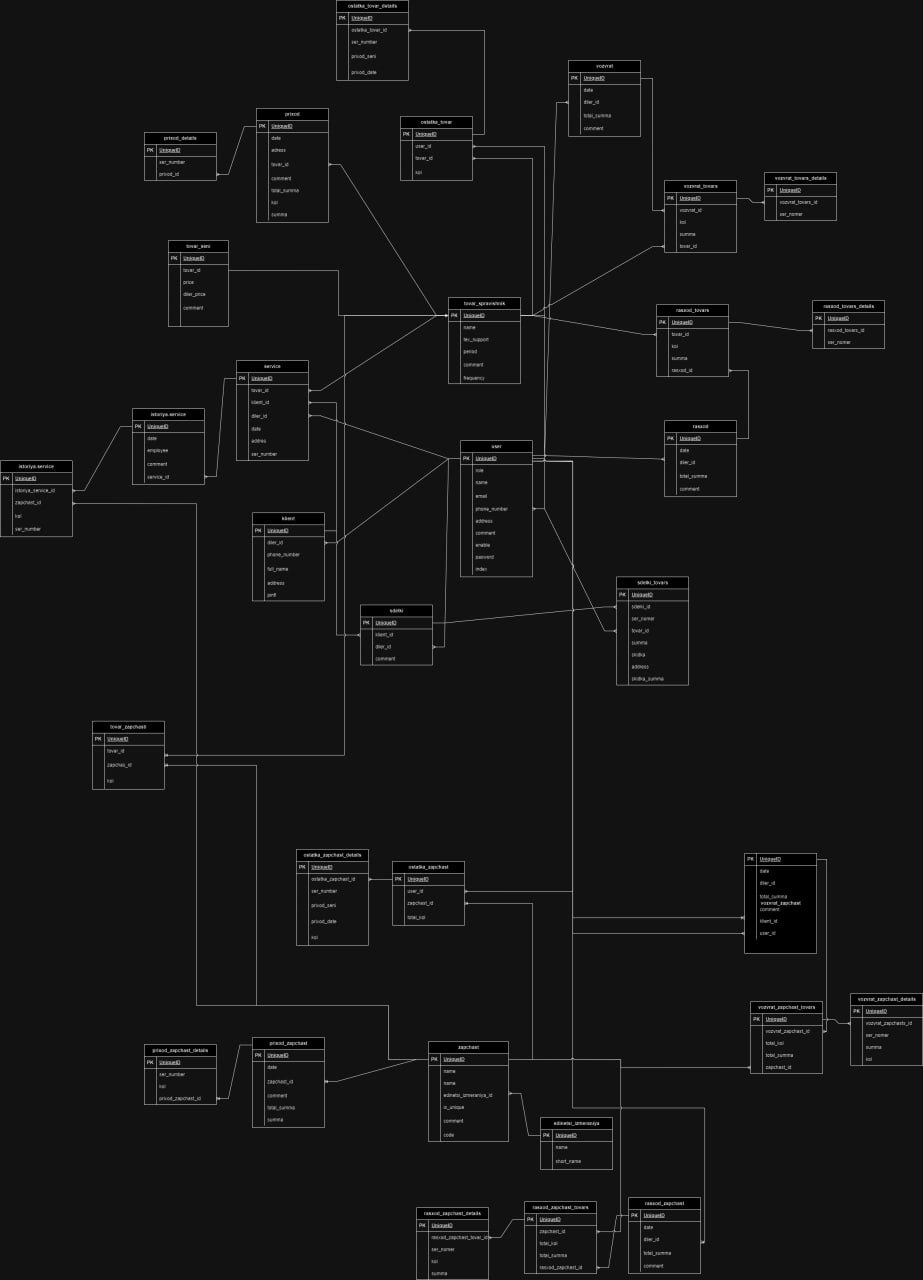

System Architecture Development

We developed a flexible architecture that allowed us to include modules for managing orders, products, warehouse stocks, service work and distributors.

Stage №4

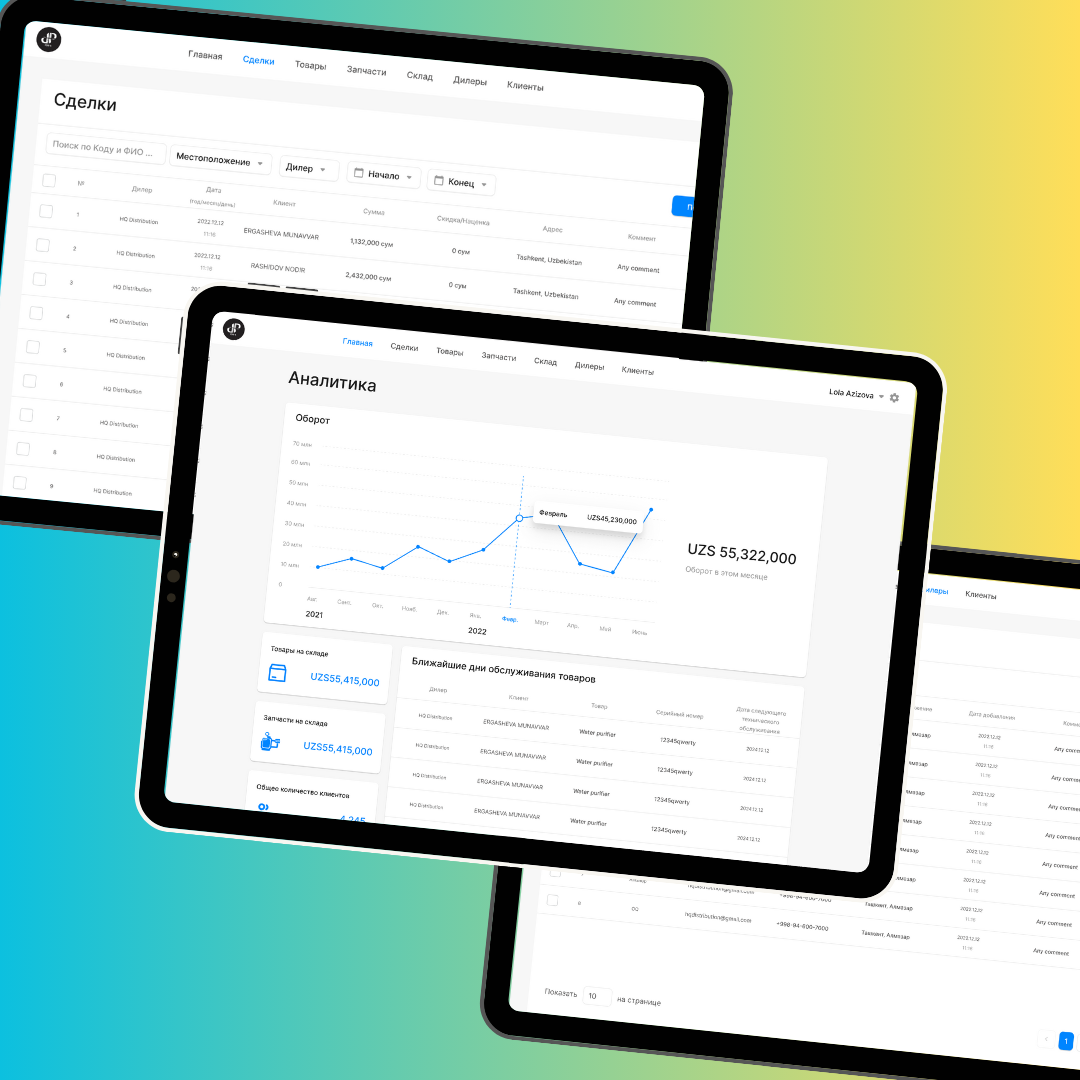

Frontend development

The interface was developed with the convenience of PSPE-K users in mind. It made it easy to track the status of orders, manage prices, and plan and control the process of replacing spare parts.

Results

The CRM system we implemented gave PSPE-K the following advantages:

Optimization of business processes

Increasing the efficiency of working with orders and managing warehouse stocks.

Effective planning

The ability to strictly plan and control service maintenance and replacement of spare parts, which ensured the smooth operation of the equipment.

Improved interaction with dealers

Simplification of order and distribution management for dealers, which has increased transparency and control over processes.

Flexibility and scalability

The CRM system easily adapts to changes in the PSPE-K business and makes it possible to add new functions and modules without the need for a complete replacement of the system.